Some Notes on Various Connector Types

This describes some of the features of connectors met in vintage equipments and is designed to help in recognition and correct description.

It is not a catalogue, merely a guide - I do not have them all available but do have a few and may be able to assist.

I shall add types as I get time.

| 1. Pattern 104 - Plessey Circular | ||

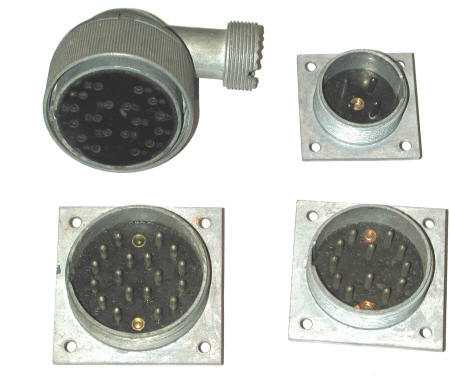

This range was widely used on military equipment from about 1945 and is still available today. The origins of the design is seen in the Air Ministry range of connectors in use from about 1938 to 1945. Some of these (4, 12 and 18 way) are shown in the picture to the right. These had zinc diecast bodies with the fixed versions using the 4-hole square frame as seen in the pattern 104 brass connectors. The hood assembly for the free connectors is similar in concept to the Mk4. The inserts use a sandwich construction secured by screws which permits interchange as with the Mk4. There is no provision for polarisation change as there is only a single key location. The first pattern 104 was designated Mk 4 by Plessey; they were made of aluminium with fine threaded coupling. Plessey also manufactured the Mk 7 - to pattern 104 - which had improved mechanics and sealing. A coarse threaded brass version using the same contact blocks is suitable for more robust environments. The coarse and fine types do not inter-mate. Contacts range in number from 1 to 25 in 3 shell sizes with 5 contact sizes providing current ratings from 5 (2.4 military) to 60 amp.The military aviation voltage rating is 350 dc or 250 r.m.s. at 45 to 60 Hz. The aluminium types were also made with a drab olive finish; this is standard in the Mk 7. The Mk 7, category T4 with blue-grey inserts is suitable for temperatures from -55oC to +100oC. The T6 category with green inserts extends the temperature to +150oC. Manufacturers included Smart and Brown and AB. Compatible connectors are still made by Weald Electronics in their LMF and LMG ranges which correspond to categories T4 and T6. See HERE for part number cross-references. |

Air Ministry 10H series Connectors. From top left clockwise 10H/418, 10H/391, 10H/395, 10H/396. See also Breeze Connectors. These are similar in general appearance but have an internal thread. |

|

CONNECTOR SIZES |

The range comes in 3 sizes, Small, Medium and Large. The fixed connectors fit chassis holes of approximately 22, 27 and 37mm diameter. Over the threads on fixed types they measured 21.3mm (0.84"), 26.8mm (1.06"), and 36.4mm (1.43") for the 3 sizes. Each has a flat on one side. |

|

Small, Medium and Large |

||

FIXED PLUGS & SOCKETS |

The range defines a socket as having socket

(female) contacts and a plug as having pins (male) contacts. The fixed part is always a receptacle in this range so "fixed" and "free" are adequate to define the shell type. |

|

Medium Fixed Socket Medium Fixed Plug |

||

FREE PLUGS & SOCKETS |

These are cable mounted and are supplied without the shroud, and cable clamps. These are made in various types to suit cables. |

|

Small Free Socket Small Free Plug

|

||

COUPLERS |

The Coupler Plug or Socket is cable mounted and permits coupling two cables. |

|

Small Free Plug Small Coupler Plug |

||

| COARSE THREADS |

Pattern

104 - Mk7 - Brass. The complete range is also available in the coarse threaded

version which is made of brass instead of aluminium and are designed for robust service.

The fixed connectors are available with 4 hole flange mountings. The picture shows the comparison between them. The two on the right are medium free plugs. Although the contact blocks are interchangeable the connector shells do not inter-mate.

|

|

Medium Coarse Coupler | Small Coarse Free | Small Fine Free |

||

| ACCESSORIES | Various accessories are available such as the set for

screened cable for free and coupler connectors (shown at right). Also manufactured with cable clamp. |

|

Mk7 Accessory Set for Screened Cable

|

||

| POLARISATION | Both the fixed and free body shells have keyways. The contact blocks can be positioned within the shells in several positions. This prevents connectors with the same contact blocks from being mis-mated. It is possible, with the Mk4, to reposition the blocks within the shells by unscrewing the slim slotted nut which surrounds the contact block at the rear. | |

|

INSTALLATION and USE |

The circular fixed connectors should always be mounted using a shaped hole, with a flat, rather than a plain circular hole. Because the torque require to fit the free connector to the fixed, there is a tendency for the fixed to rotate. This can damage the rear wiring and also make mating difficult. This is particularly true of the large size with multiple contacts such as the 25 way. It is helpful to lightly oil or lubricate the aluminium threads with silicone grease. A firm pressure on the free connector to assist mating should be applied once correctly engaged rather than relying on the screw action to pull in the contacts. The soldered connections should be individually sleeved with neoprene sleeves or, with care, heat-shrink sleeves. This not only prevents possible shorts from stray wire "whiskers" but acts as a support to the wires. Again this is particularly required in the dense multi-way connectors such as the 25. |

|

| FURTHER NOTES | There are many special versions of these connectors. For example double-density types were introduced to provide 12 contacts in a small size shell. Lower density types such as 6 contacts in a medium shell provided for higher voltage operation. | |

Copyright www.ElectroJumble.org and www.ElectroJumble.org.uk |

||

Updated 03 October, 2024